Generally, “low pressure” can mean “easygoing” or “relaxed.” In industrial finishing terms, it refers to using less air by adjusting the fluid’s speed out of a spray nozzle to apply smooth coatings on detailed or delicate surfaces.

What is Low Pressure Spraying?

Low pressure spraying uses reduced air pressure to control the spray pattern, leading to less overspray and better overall results. Industrial finishing facilities use the technique to achieve a fine finish and lessen material waste.

“You need to relax the material, and then the air can break it up,” says Ian Skoglund, technical sales and process support manager, ICAFe Companies.

Skoglund likens it to the classic game of Red Rover in this video from an industrial finishing training at SenecaFTI in Baldwyn, MS.

Reducing air pressure to control a spray pattern not only leads to less overspray and better overall results with paint, but it also works well with adhesives.

Low pressure spraying of glue to assemble car components or upholstery can be like spraying paint, according to Terry Nelson, business manager for hot melt and adhesive applications.

“There really isn’t much difference between spraying glue and paint,” says Nelson. “You work with the same type of equipment and need to adjust pressures to get the best results.”

How to Set Up Low Pressure Spray Guns

While helping industrial painters set up spray guns for low pressure applications, Skoglund gets them started with these steps:

1. Connect the air supply hose, air pressure regulator, and fluid supply hose to your air spray gun, as instructed in the manual that came with it.

2. Choose and position the air cap for the desired spray pattern.

3. Set the fluid pressure regulator, as instructed in the manual that came with it.

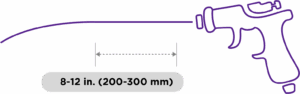

4. Adjust the fluid flow with the air pressure regulator until the stream from the gun travels 8 to 12 inches (200 to 300 millimeters) before falling off.

5. Check your fluid pressure.

- If the fluid pressure is too high at the desired flow rate, install a larger nozzle.

- If the fluid pressure is too low at the desired flow rate, install a smaller nozzle.

“If you go with a bigger fluid nozzle but ease up on the pressure, you’ll still get the same amount of material coming through. The difference is that it moves slower,” says Skoglund. “And that slower stream gives the air more time to mix in and break up the fluid for smoother, cleaner atomization.”

A slower stream with the right amount of air also makes a big impact when spraying adhesive.

“You want the spray pattern to have wider ropes, so that you have more glue that makes a better bond,” says Nelson, who designed an air cap for his customers who spray adhesive.

He simply describes his design by saying, “Air caps with less holes work best for glue.”

Liquid Finishing and Adhesive Expertise

Whether you’re a large operation or a small shop, experts like Nelson and Skoglund are part of any liquid coating or adhesive application solution by ICAFe Companies.

Explore industrial equipment solutions for…