If you want to know about electroplating, ask Bob Campbell. The certified electroplater finisher (CEF) has been plating since he was 18 years old.

If you want to know about aerial refueling planes, also ask Bob Campbell. Six years into his electroplating career, he joined the Wisconsin Air National Guard’s 128th Air Refueling Wing.

“I wanted to do my part, but didn’t want to quit my job,” says Campbell.

As he approaches 16 years with ICAFe Inc. on August 16, the technical sales and process support technician reflects on how his military and manufacturing experience have connected over the years.

The 'Old Man' from Milwaukee

Inspired by his dad, who served in three different branches of the military, Campbell started his military service in 1990 as an airman, basic enlisted grade 1. During basic training, the 25 year-old became known as “the old man” from Milwaukee, WI.

“Almost everyone else was fresh from high school,” recalls Campbell.

As part of the 128th Air Refueling Wing, Campbell was deployed twice to support fighters enforcing no fly zones.

- In 1994, he served in France during Operation Southern Watch over Iraq.

- In 1995, he went to Germany as part of Operation Deny Flight over Bosnia-Herzegovina.

“We supplied everything from water for the airmen to jet engine fuel and tires for the planes,” says Campbell.

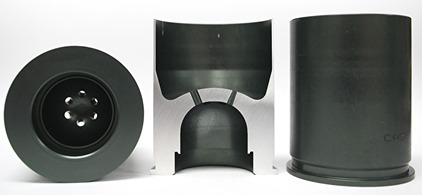

During both deployments, Campbell noticed electroplating in action. He recognized electroplated components in his company’s KC-135 Stratotanker aerial refueling planes. He also saw shells plated at the factory, where he serviced chemically (the electroplating process of applying a thin layer of metal to the surface of a base metal).

Campbell worked his way up to staff sergeant, enlisted grade 5, by 1998, when he was honorably discharged from the Wisconsin Air National Guard.

“It was rewarding to serve my country with people who are like family,” he says.

Calling on Military Subcontractors

Campbell still appreciates his military and manufacturing connections.

As part of his outside sales role with ICAFe Inc., he regularly calls on the factory where he got his start in electroplating.

“We supply and support the industrial electroplating equipment used to make ammunition shells more durable for the Air Force and Navy,” says Campbell.

Electroplating Solutions

ICAFe Companies is a leading provider of aqueous systems and integration services to plating customers throughout the Midwest United States. For more about ICAFe Companies’ electroplating capabilities, visit icafecompanies.com/electroplating-systems.