electroplating

Industrial Electroplating and Aqueous Systems

We design, engineer, integrate, and support turnkey plating lines and advanced automation systems that meet the high demands of modern manufacturing. Our electroplating solutions enhance product durability, finish quality, and process efficiency — helping plant managers and tier suppliers achieve consistent, scalable production outcomes.

What We Offer

Filtration Systems, Media and Parts

- High-performance filters: Serfilco, Mefiag, Slimline, Flo-King

- Filter pumps, cartridges, disks, paper, and bags

- Flo-King accessories and rebuild services

- Filter presses, cloths, and parts for all major brands

Pumps and Kits

- Diaphragm pumps: Graco, Wilden, ARO, Sandpiper, Yamada, Warren Rupp

- Brightener feeder pumps: JP Tech, LMI, Pulsafeeder, Pulsatron, Mesa West

- Drum pumps: Lutz, Serfilco, Finish Thompson, Galway, Flux

- Chemical-resistant sump pumps: Perfecta, BJM

- Rebuild kits and replacement parts

Heat Exchangers and Temperature Control

- Serpentine, grid, plate, and frame coils

- George Fischer PVDF exchangers

- Electric heaters, RTD sensors, fuses, and controls: Process Technology, Clepco

- Palm heat exchangers and controllers

Tanks, Liners and Repairs

- Custom-built tanks: poly, steel, stainless, fiberglass, lead

- Molded tanks and drop-in liners: PVC, Koroseal

- Rigid tank liners

- In-house tank repair services

Air Handling and Scrubbing Systems

- Ventilation systems and fume scrubbers

- Scheduled maintenance and repair services

Plating Barrels and Spin Dryers

- Plating barrels: Hardwood, Singleton, Napco

- Spin dryers: Auto-Technology, New Holland, Desco

- Baskets and danglers in poly, steel, and stainless

Additional Equipment and Services

- Turnkey plating lines and equipment installation

- Salt spray chambers, wet/dry vacs, chillers, air agitation blowers

- Fiberglass I-beams, tank magnets, GF Signet instrumentation

Why Aqueous Systems Matter in Electroplating

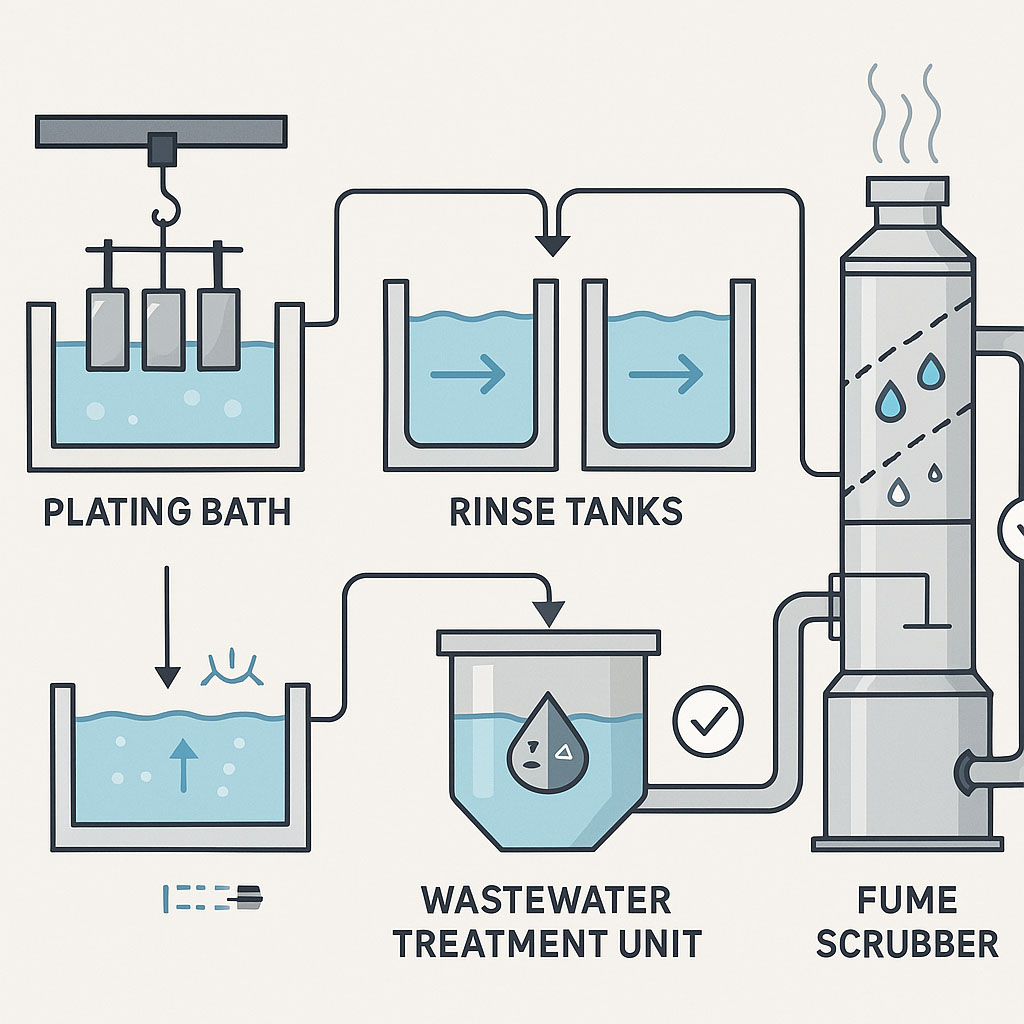

Aqueous systems — water-based chemical processes — are essential to high-performance electroplating. They enable:

- Precise bath control for cleaning, rinsing, and plating

- Environmental compliance through wastewater treatment and emissions control

- Reliable process performance via consistent temperature and chemical balance

Contact us to ensure your plating operations are safe, efficient, and fully compliant, especially in high-volume or regulated environments.

Electroplating and Aerial Refueling

If you want to know about electroplating, ask Bob Campbell. The certified electroplater finisher (CEF) has been plating since he was 18 years old.

If you want to know about aerial refueling planes, also ask Bob Campbell. Six years into his electroplating career, he joined the Wisconsin Air National Guard’s 128th Air Refueling Wing.

The technical sales and process support technician reflects on how his military and manufacturing experience have connected over the years.

Contact Us

Connect with an Electroplating Expert

Have a question about plating systems, equipment, or integration? Our electroplating and aqueous system specialists are here to help.

Send us a message, and we’ll do our best to respond within 24 hours.